Based on many years of experience in diamond concentration both in the conditions of the Republic of Sakha Yakutia and in Africa, NPK GRAVICON offers both separate jigging machines with a system of superimposed oscillations for a capacity of 10 ... 100 tons per hour, and modular complexes for the enrichment of alluvial deposits diamonds with a productivity of 10 ... 50 tons / hour. Two such complexes were developed by us and successfully implemented in Guinea and Liberia. There is a variant of the complex for coastal basing and there is a variant of placing equipment directly on the dredge.

Also, in 1989, the specialists of our company, together with the Yakutniproalmaz Institute, developed and subsequently modernized the grease separator SL-10. The first prototype was introduced at the Aikhal GOK. Over the past years, the control system has undergone significant changes, being equipped with a modern industrial controller and an operator touch panel.

Grease separators are devices used for enrichment of minerals, in particular at the final stage of finishing of diamond-bearing ores. The principle of operation is based on the difference in the wettability of useful particles and tails.

The principle of grease separation has been known for a long time. With the active participation of an employee of the company NPK Gravicon Alexander Sergeevich Rule, under the auspices of the institutes "Yakutniproalmaz" in Mirny and "Gipromashobogashchenie" in Lugansk, a conceptually new design of the separator was developed, which was reflected in the patent (http://www.freepatent.ru/patents/2038852)

"Claim

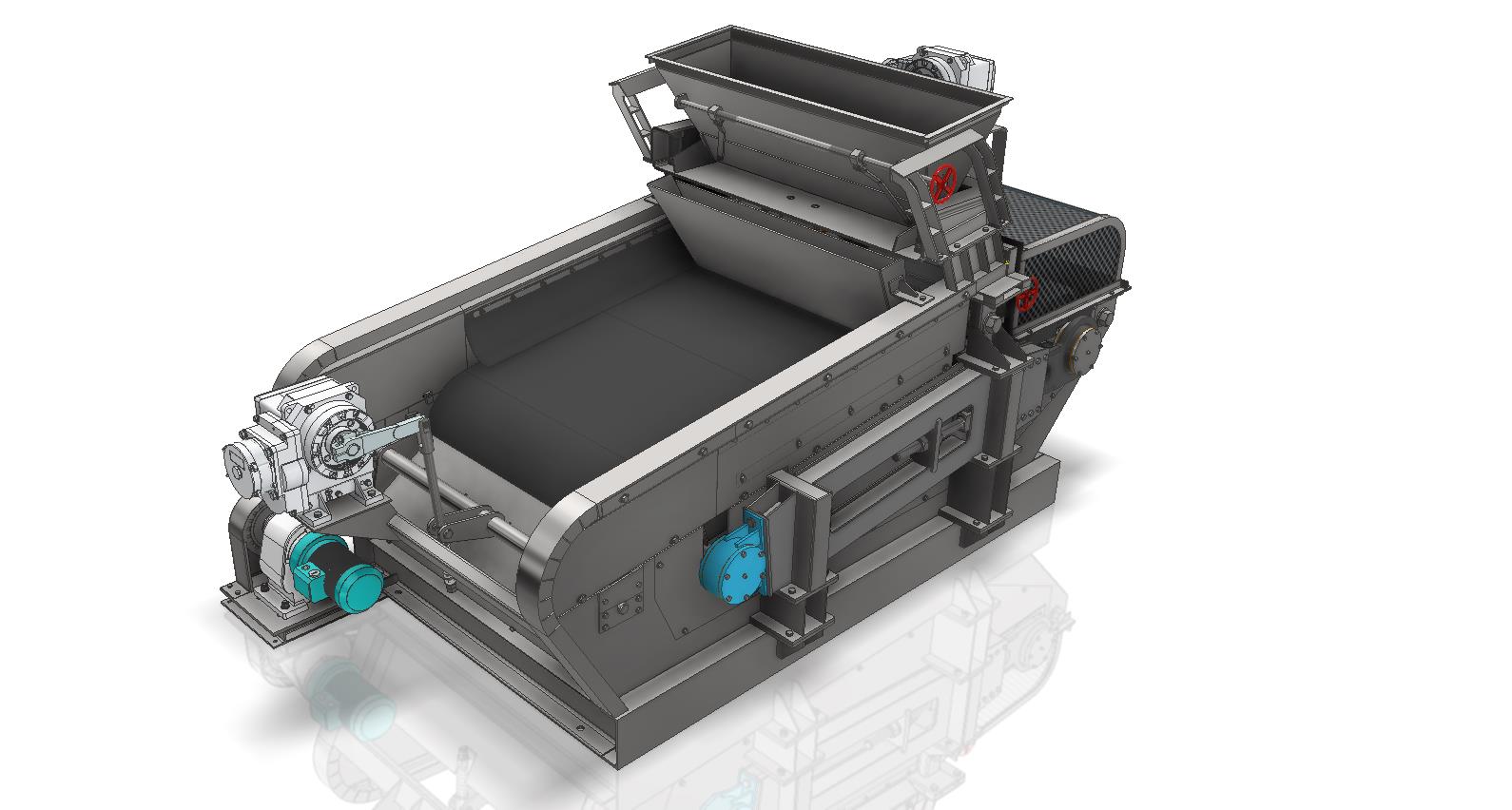

GREASE SEPARATOR, including a body with an endless belt located in it, enveloping the driving and driven drums, a feeding hopper with a feeder located at the driving drum, a vibrator, a sprinkler, a spreading box, receiving hoppers, characterized in that, in order to increase the extraction of the oleophilic component, the axis driven drum is rigidly connected to the vibrator and mounted on shock absorbers with the possibility of vertical movement.

As can be seen from the formula, it was in this design that the idea of forced vibrations of the belt was implemented, which made it possible to significantly increase the extraction of oleophilic particles from the starting material. During the winter of 1991. Testing a prototype at the Aikhal Mining and Processing Plant, the optimal frequency and amplitude of vibrations were determined, the requirements for the automation system were determined, and most importantly, the high efficiency of grease separators of the SL type was shown.

The company NPK Gravikon continued to modernize these devices, which was reflected in the model range SL-05M, SL-10M and SL- 20M for productivity from 3 to 10 tons per hour for the original product.