Over the years of our work at the Design and Engineering Institute "GIPROMASHUGLEOBOGASHENIE", which was the industry leader in the USSR and the CIS, and over the following decade of GRAVICON-EUROPE operation, we have developed and implemented equipment for concentration of the widest range of ores and non-metallic materials, for which the concentration by hydraulic and air jigging is considered optimal, these are:

- manganese ores >>>>>>>;

- tin ores (cassiterite);

- lead ores;

- tantalum-niobium ores >>>>>>>;

- chrome ores;

- iron ores >>>>>>>;

- polymetallic ores (separation of collective concentrate);

- gold ores;

- titanium ores >>>>>>>;

- barites;

- vermiculite (hydrated mica group);

- garnet sands >>>>>>>

The standard dimension range of GRAVICOM type Jigging Machines, developed by our Company, have modifications designed for concentration specifically crude ores according to the design of compartments, vortex-finders and pneumatic actuator.

For ore concentration the following equipment is applied:

- classic water-pulsating Jigging Machines >>>>>>>;

- machines with movable sieve >>>>>>>

- and false-bed Jigging Machines.

The last-named have well proved themselves in dressing of small sizes ("minus" 1…2 mm) and such hard-to-dress raw materials as vermiculite.

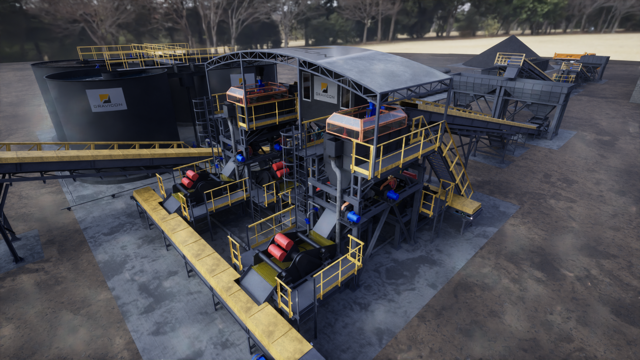

"Turnkey" solutions are used as well.

|

|

|

|