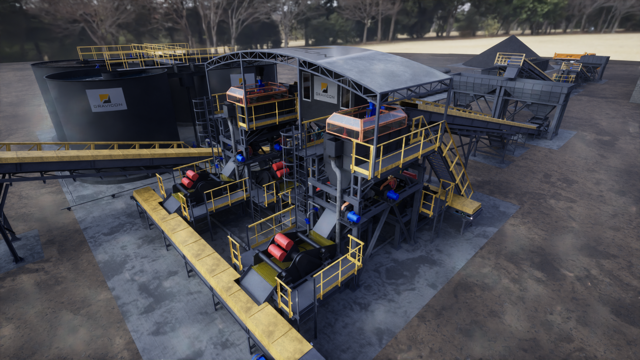

GRAVICON-Europe designs and supplies "turnkey" bespoke modular concentration plants for concentration of wide range ores; extractive waste and slag; washing thermal, coking and anthracitic coals with capacity of 25-400 t/h. This is an analogue of a full-featured Preparation Plant (PP) with lower capital expenditures and preparation costs, fully closed water-slurry circuit and tight implementation time.

In 2021, the GRAVICON company developed and launched into pilot production modular plant based on a new generation of hydraulic jigging machines with a movable sieve. The new generation of these jigging machines is based on a modern linear servo drive. Automation provides the dynamics of movement of the concentrating material, which is not achievable for jigging machines of the previous generation and classic air-pulsating jig. Thanks to this, an increase in productivity from 1 m2 of a working sieve and in the quality of separation of beneficiation products is achieved.

Benefits of the new equipment for the customer:

-the installation time of the complex is reduced by 3-4 times to 15-20 days;

-no foundations required, installation on a prepared site;

-energy consumption is reduced by 2 times;

-the amount of recycled water is reduced by 4 times;

-the required volume of circulating water reservoirs is also reduced by 4 times.

-compactness: the height is reduced by 2 times, which makes it easier and cheaper to cover the processing module for all-season operation. The small size of the recycled water tanks also allows them to be located inside the building.

| The parameters of the complex with a capacity of 50 tons per hour are given in the table: | ||

| Parameter | ||

| Capacity | t/h | 50 |

| A class of concentrated raw materials | mm | 0-50 |

| The density of raw materials | g/cm3 | 1,1..23 |

| Accuracy of density separation | g/cm3 | 0,1 |

| Electricity consumption, no more | KWH | 70 |

| Recycled water | m3/h | 50 |

| Dimensions of the support, LxWxH | m | 8х6х6 |

| Recycled water tank volume | m3/h | 150х3 |

| Foundations | "-" | |

| Installation time on the site | days | 15-20 |

| Duration of the guarantee | months | 24 |

| Lifetime | years | 10 |

|

|

Among all common methods for coal preparation (hydraulic jigging, flotation, dense-media preparation and pneumatic separation), jigging exclusively dominates by cluster of features (preparation costs, environmental compatibility, capital expenditures, quality of concentrate, in-use simplicity) in the industry sector as far as concerned creating new modular complexes at sites of coal mining or replacing obsolete worn-out models.

Comparison with alternative technologies:

Flotation: used if there is a need for preparation of a large amount of size "minus" 0.5 mm and below. Capital expenditures are 5-7 times higher, preparation cost is 2-3 times higher, application of chemical agents (including toxic and flammable, which are necessary (a) to buy, (b) to store, (c) they fall into the circulating water, causing environmental pollution), high demands for attending personnel qualification, expensive and wearing out control system components (flow meters, densitometers etc.), area of preparation site (with manifolds) is 3-4 times larger, inability of outdoor installation. An expensive, environmentally unfriendly technology, which, however, is effective in the preparation of a large number of micron sizes. GRAVICON SPE, being an inheritor and successor of achievements of GIPROMASHUGLEOBOGASHENIE Institute in terms of gravity separation, supplies MFU series flotation machines complete with control system and chemical agents feeding >>>>>>>

Heavy media: preparation cost is 3-4 times higher due to the larger number of attending personnel (up to 15 men per shift), substantially greater energy consumption (4...5 kW per ton of initial product), need to regularly purchase magnetite, as up to 4 kg is used with each ton of rock and concentrate. Circulating water is not clean, but contaminated with a weighting agent and the requirements for quality of circulating water clarification are substantially higher than in jigging. Based on the aforesaid, payback periods of projects are long and take up to 3-4 years. Moreover, during periods of reduced coal prices, production cost of the power-generating coal concentrate is even close to its market price.

Pneumatic separation: indispensable when there is no water at all, even 5 m3/h. It reduces ash content by 5-10% per pass, depending on initial product. The initial product humidity should not exceed 5%. With increasing the humidity of environment (rain, snow) or material, the separation degrades in quality or takes no place at all. The presence of clay is not allowed (for jigging, the presence of clay up to 15...20% is generally not a problem even without the use of additional mechanisms (such as trommels and their analogues) in

the head of engineering process). Expensive, large-format aspiration system, complications of storage, transportation, disposal of large amount of fine dust. Inability to obtain low ash concentrate. Honest manufacturers of this type of equipment no longer call it "preparation equipment", but use the term “equipment for preliminary cleaning of rock”, which fairly presents its functionality. Moreover, in dry hot environments it is desirable to comply with critical requirements for the moisture content of initial raw material.

If in the course of jigging under strict moisture requirements for concentrate, only the concentrate itself requires dehydration/drying, then during pneumatic separation it is necessary to dry the entire initial product, in order to ensure year-around operation, including periods of high humidity.

GRAVICON-EU, following traditions of Preparation Machines Department of the GIPROMASHUGLEOBOGASHENIE Institute, supplies advanced PSM series pneumatic separators for preparation of mine coals and terricones >>>>>>>

Dry coal cleaning (with cyclones, vacuum) has all the disadvantages of traditional pneumatic separation including those, specifically related to this technology:

- initial product humidity should not exceed 7%, which is difficult to achieve in areas with moderate and continental climates, i.e. the separation is possible in the dry hot season only;

- high energy consumption up to 1,500 kW, which in terms of a ton of initial product is 2.5...3 times higher than that of jigging;

- very large areas of the plant (up to 5 hectares or TEN football fields). As a result, it is impossible to arrange the plant sheltering in a financially expedient way, which makes impossible its operation in severe climatic conditions;

- no intermediate product is recovered during preparation, which causes either tailing losses of useful product or increase in the ash content of concentrate;

- only narrow-classified material is processed, since in contrast to jigging, heavy media and pneumatic separation, the separation does not occur by material density, but by its weight. Jigging involves many forces acting on the material and the result of their interaction is separation in density. This technology involves the only strictly vertical force acting on the material. Consequently, the material should be located in one layer and have (preferably) exactly the same size. With a difference in particle size, smaller pieces of rock will have less weight than larger pieces of coal, resulting in rock penetration into the concentrate;

- materials with large difference in density of useful material and tails are separated. Jigging indicators with 0.1 g/cm3 delta between the concentrate and rock are unobtainable for this technology;

- low capacity of 1 m2 of the conveyor working surface: good quality separation is possible only when the material is positioned in one layer or one layer and a half.

GRAVICON-EU is the developer and manufacturer of three of five possible categories of coal preparation equipment (Jigging Machines, flotation machines, pneumatic separators) and is ready to supply any of them at customer’s request.