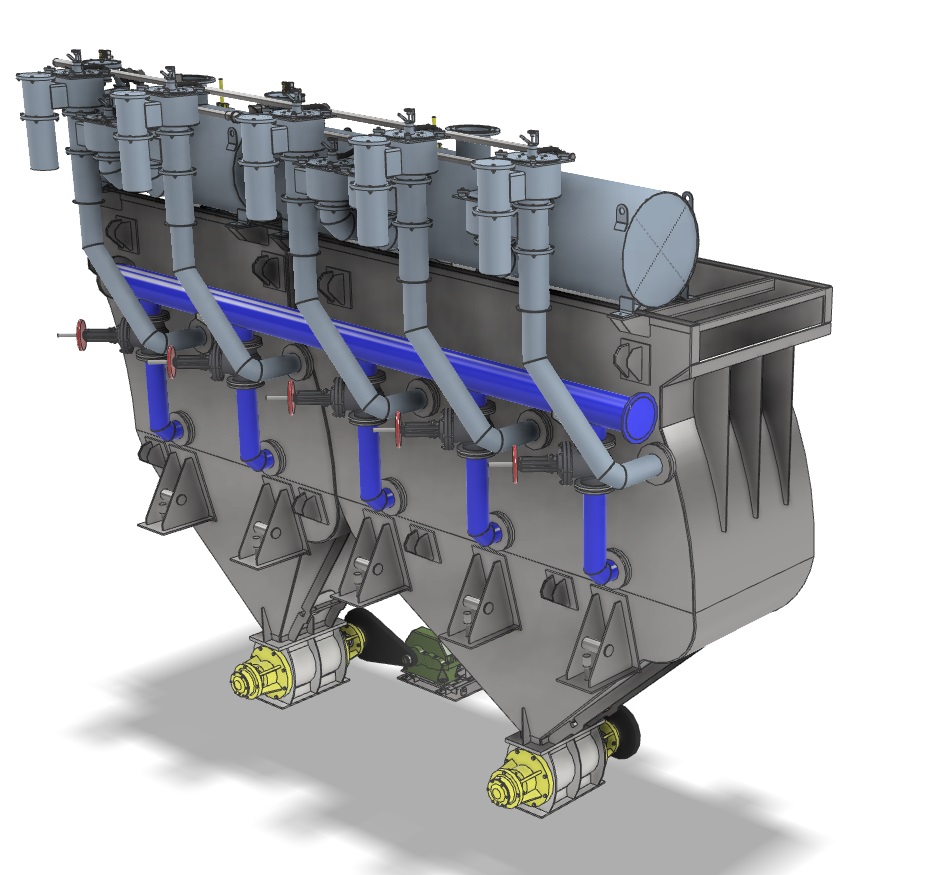

The GRAVICON company designs, manufactures, and implements jigging machines, both water-pulsation and moving sieve. Production time is 1-3 months depending on productivity and completeness.

Jigging machines of the GRAVIKOM type with elevatorless unloading not only reduce the cost of operating costs and increase reliability, their main advantage is that the volume of recycled water settling tanks is reduced by 8-10 times.

Jigging machines are designed for gravitational concentration in the aquatic environment. They are used for dressing and concentration of coals, ores of ferrous and non-ferrous metals (Mn, Cr, St, Pb, Ti, Ta, Nb, W, Ni etc), alluvial gold, diamonds, as well as dumps of metallurgical, ferroalloy industries and waste heaps. Provide high separation efficiency. Enriched material class 0.2...200 mm. In the area of the specified limit values, special versions of jigging machines are required.

We can always offer you the best solution for your specific task based on existing jigging machines. Or, if necessary and expedient, we can develop a jigging machine exclusively for your material. As is known, the productivity of a jigging machine depends on the width of the compartments, and the quality of the concentration depends on the total length of the working surface of the sieves. The standard size range of serial jigging machines perfectly corresponds to the serial production of equipment and processing plants, but does not allow obtaining the optimal result in a particular case. Being the developers of jigging machines, based on the analysis of raw materials for washability and in accordance with the performance required by the customer, we design OM that allows you to get the maximum enrichment efficiency of your source material. This approach has repeatedly proven its cost-effectiveness. So, in response to the growing demand, we have developed jigging machines for the washing of oxidized coking coals, jigging machines for the cleaning of coarse-grained sludge etc. The jigging machines developed by us have long been successfully operating in Ukraine, Russia, Kazakhstan, Uzbekistan, Turkmenistan, China, Mongolia, Guinea, Liberia, Angola and other countries.

As practice shows, if the material can be concentrated by jigging, then this variant will be the most effective of all possible technologies in terms of the aggregated parameter "quality + quantity + cost_of_processing". The result is achieved due to the low energy intensity of the process (in comparison with heavy media and pneumoseparation - at times), the absence of chemical reagents in it (unlike heavy media and flotation), undemanding to the moisture content of the source, its size and density (unlike pneumoseparation) , small staff and undemanding qualifications (in contrast to heavy media and flotation especially), low capital costs and the shortest implementation time in the industry. Plus, a huge number of technological levers of influence on the enrichment process to achieve the required quality indicators (unlike any other enrichment method) with the possibility of obtaining up to four products in one process.

| Name of parameter | Gravicon -5*2 | Gravicon - 8*2 | Gravicon –12*2 | Gravicon-18*3 |

| (analogue of jigging machine105 ) | (analogue of jigging machine 208 ) | (analogue of jigging machine 312 ) | (analogue of jigging machine 318 ) | |

| Capacity on initial product not more than , t/h | 50 | 100 | 200 | 300 |

| Mass, t not more than | 9,9 | 15,9 | 20 | 28,5 |

| Material to be separated | Coal / ores of ferrous and non-ferrous metals | |||